About ITW EAE ITW EAE is a division of the Illinois Tools Works, Inc. (NYSE: ITW), a Fortune 200 global industrial manufacturer with operations in 58 countries. ITW EAE is a developer and provider of capital equipment used in electronics manufacturing, and is found in premier printed circuit board (PCB) assembly facilities the world over. ITW EAE comprised with industry-leading brands: MPM stencil printing equipment for electronic materials; Camalot Systems fluid dispensers; Electrovert wave soldering, and curing, and cleaning equipment; Vitronics Soltec selective soldering, reflow soldering and wave soldering equipment; and Despatch industrial oven and furnaces.

ITW EAE manufacturing centers are located in Camdenton, Missouri, Lakeville, Minnesota, USA; and in Suzhou, China. Sales and support offices are located in Franklin, Massachusetts, USA; Lakeville, MN, USA; Camdenton, Missouri, USA; Guadalajara, Mexico; Singapore, Suzhou, China; Oosterhout, Netherlands; and in Frankfurt, Germany.

Speed, stability, and precision are hallmarks of CAMALOT dispensing machines. Innovative gantry designs even in smaller, more compact footprints enable rapid acceleration for faster throughput, while at the same time providing bedrock stability that enables the highest level of precision for applications ranging from solder paste to underfill to adhesive dispensing and advanced ‘jetting’ techniques.

Shenzhen JT Automation Equipment Co., Ltd., stock code 300400, was established in 1997 and was restructured into a joint-stock company in 2004. It is currently a domestic manufacturer and supplier of special equipment integrating R&D, production and sales. It is a national high-tech enterprise. In 2019, the company's reflow soldering equipment won the single champion product of the Ministry of Industry and Information Technology. The company has about 1,100 employees. It has built two industrial parks in Shenzhen, equipped with a full set of production facilities and adopted an independent production mode. The products mainly include electronic manufacturing production and testing equipment, semiconductor equipment and special equipment for the optoelectronic display industry. Various electronic and optoelectronic products such as communications, mobile phones, automotive electronics, wearables, semiconductors, etc., provide intelligent equipment and solutions.

From prototyping to high-volume production, we have the equipment line-up to suit your surface mount technology needs. Our team has established a variety of pre-arranged lines of equipment to help your company un-complicate and succeed at starting or expanding in-house assembly.

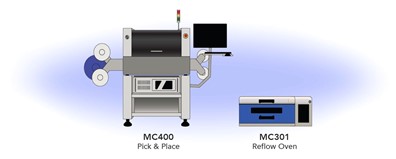

This line includes a fully integrated paste dispenser. It places parts from 0201 to 100 x 150 mm at 3,000 CPH. This comes with a 2-year warranty.

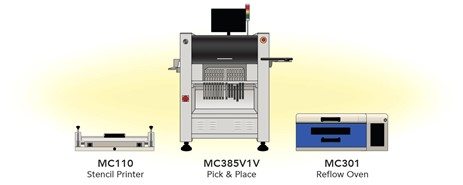

This line is the next step up from our Advanced Starter/Lab Line, with a MC110 stencil printer added for production. This comes with a 2-year warranty.

For those interested in partial automation, this workcell is a larger, more high-tech option for speeding up production in a small space. It is great for high mix boards since it has up to 128 feeder slots. This comes with a 2-year warranty.

Ramp up production speed even further by choosing a fully automatic workcell geared toward high-quality, precision, and speed for small to medium assembly needs. This comes with a 2-year warranty.

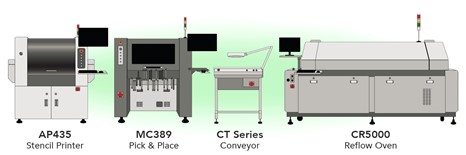

Our best-selling SMT line for OEMs; a full inline solution capable of 10,500 CPH that has 96 feeder ports for high-part-count boards. This comes with a 2-year warranty.

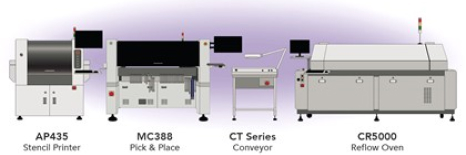

Our inline system with the MC388 added for an even higher feeder count of 192 slots for increased changeover speeds. This comes with a 2-year warranty.

Automate your entire assembly line and have it configured directly for LED board production with this specialized SMT line. This comes with a 2-year warranty.

Shen Zhen YUNI Precision Technology Co., Ltd. is a professional design and production of titanium fingers, heater elements, SMT peripheral equipment, and provide SMT equipment parts, non-standard parts design and production, equipment upgrading and one-stop service of Hong Kong enterprises. Our company always adhere to the "customer first, quality win" principle of service. In order to improve the products are widely used in the industry, the introduction of absorbing the advanced technology, combined with the requirements of customers, providing customers with different varieties, specifications of the products.

Now YUNI company has a group of advanced machinery and equipment, to absorb a large number of experienced, trained technical and production staff, set design, development, manufacturing, sales, after sale service. Our "standard management, abide by integrity, the pursuit of excellence, pragmatic and innovative" business philosophy, in good faith with customers, to join hands in creating a win-win! Your satisfaction is our eternal pursuit!

YUNI company has adopted the SGS ISO[1]9001 (2008 version) quality management system certification, strengthen the quality management of enterprises. On the internal standard operation procedures, the effective cost control; foreign increased domestic and foreign customer confidence, improve quality assurance. Future, Youming company also will continue to go beyond the self, continuous improvement, keep the leading position in the industry. Persevere, looking to the future, we are the advantages: high quality, good service, low cost, reach win-win!

McDry dry cabinet for MSL components and desiccators provide optimal ultra-low humidity and moisture-proof storage for IC packages. Moisture-sensitive components when safely and properly stored in McDry have an indefinite floor-life and micro-cracking or pop-corning during the reflow process is not an issue. Other ideal storage applications for McDry include original prints, printed wiring boards(PWBs), polymide film, tape reels, feeders and various electronic components and materials. MSD dry smart dry cabinets conform to IPC/JEDEC J-STD 033D and IPC 1601 Guidelines.

Key features of Mcdry